Product Release: Wire Rope Non-destructive Testing System

Over the past 21 years, Weite has always focused on research in the field of hoisting safety management, leading the industry to develop in the direction of hoisting equipment fault diagnosis, big data management, full life cycle monitoring services, and an intelligent hoisting ecosystem.

In recent years, new products and technologies such as sensors, monitoring instruments, and software systems researched and developed by Weite around the safety monitoring and management of lifting equipment have been launched one after another... After the "wire rope non-destructive testing system" product being put into the market, it was quickly successfully applied in portal cranes, factory bridge cranes, bridge erecting machines, gantry cranes, gate opening machines and other equipment, and has become one of the important products of Weite's innovative hard power.

Quick understanding through pictures and texts

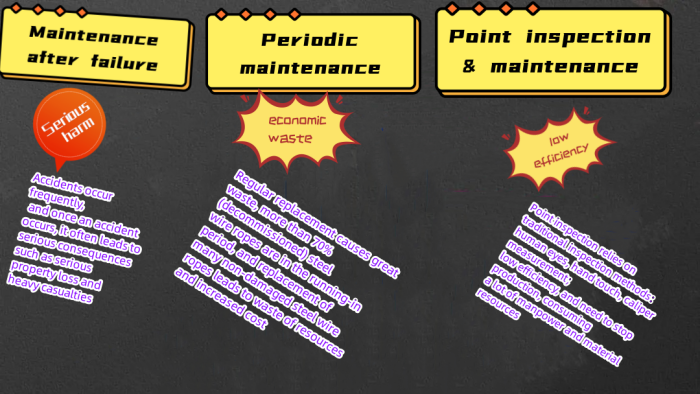

For a long time, the maintenance and management of steel wire ropes for lifting equipment has been a difficult point in the equipment management of various enterprises. Accidents caused by broken wire ropes are common, and each accident is accompanied by serious consequences such as property loss and casualties.

At present, seeing with the naked eye, measuring with a caliper, and touching by hand are still common methods for wire rope inspection. There is a huge "gap" between inspection technology and users' digital management needs.

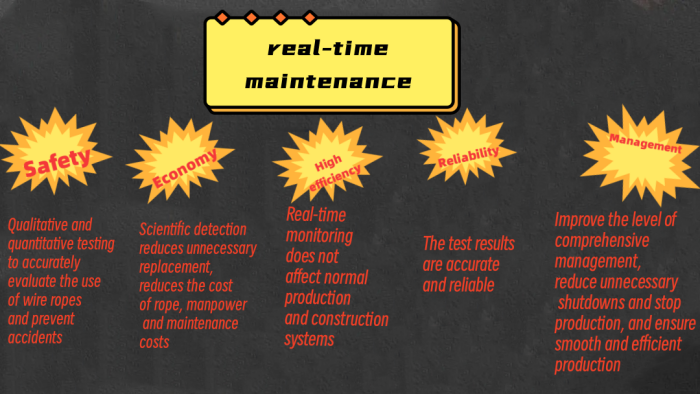

As a result, Weite launched a new type of non-destructive testing system for steel wire ropes of lifting equipment. This system has the characteristics of "high efficiency, precision, convenience and safety", and scientifically and effectively solves the current problems of automatic steel wire rope testing.

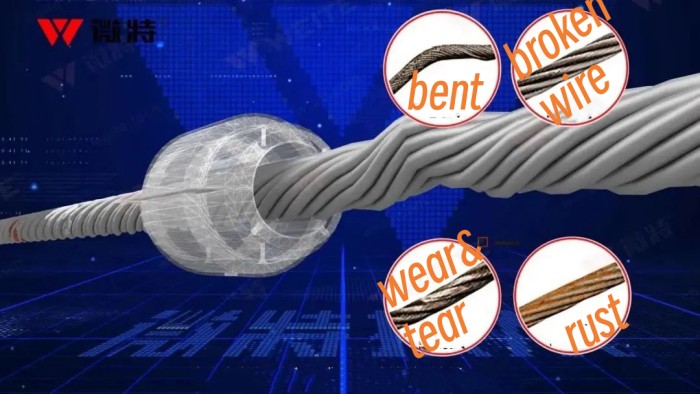

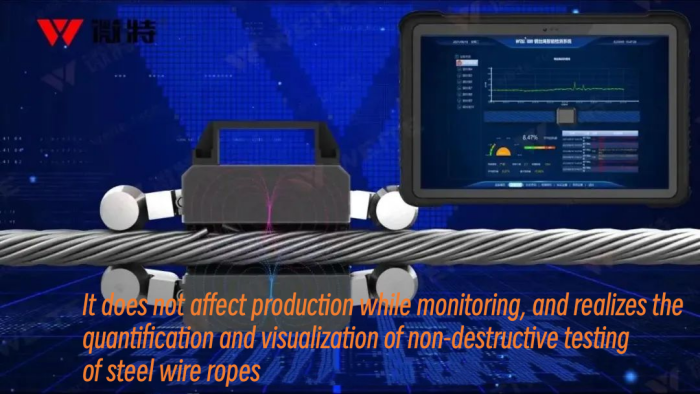

The wire rope non-destructive testing system for Weite lifting equipment is based on the theory of magnetic field radiation. By monitoring the changes of the stray magnetic field vector detection array, it can automatically collect damage data such as broken wires, rust, wear, bending, and kinks of the wire rope in real time and at high speed. Combined with multi-data fusion technologies such as wavelet algorithm and neural network, it can finally identify the damage degree and location of the wire rope damage, and provide a detection report. It does not affect production while monitoring, and realizes the quantification and visualization of non-destructive testing of steel wire ropes. The system can be connected to a remote monitoring and management platform to grasp equipment information anytime, anywhere.

Four advantages

The non-destructive testing system for wire ropes of Weite‘s lifting equipment has unique advantages with its unique testing method and brand-new industrial design:

1. The sensor does not require a special magnetization device; it is waterproof and dustproof, and there is no need to clean and maintain the surface;

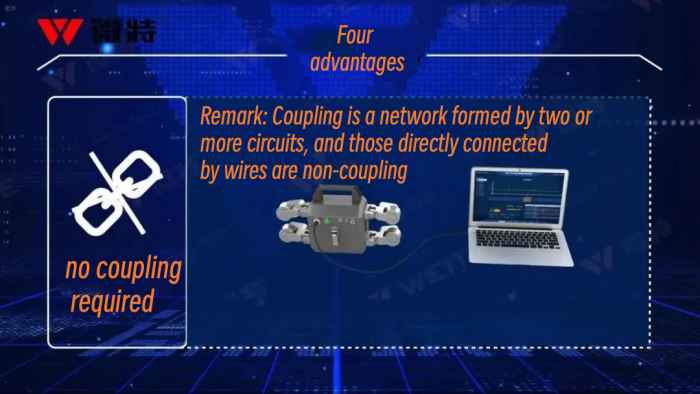

2.No coupling technique is required

3. The unique innovative algorithm can quickly and accurately detect the location of stress concentration; the detection accuracy is high, the error of the number of broken wires in the lay length can be less than 1 wire, and the accuracy of damage point positioning can be more than 95%, which greatly improves the safety factor of the wire rope.

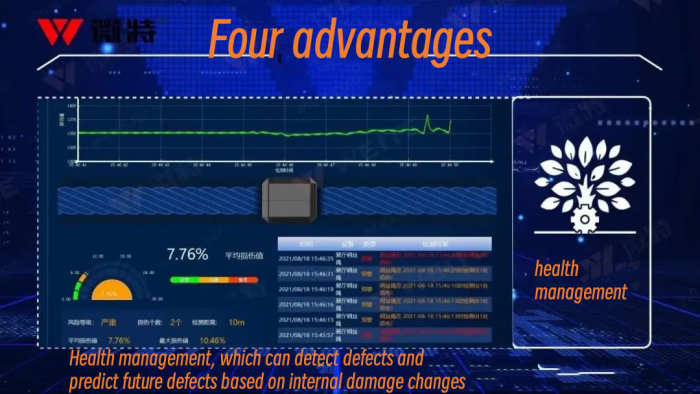

4. Health management, which can not only detect existing defects, but also predict future defects based on internal stress changes.

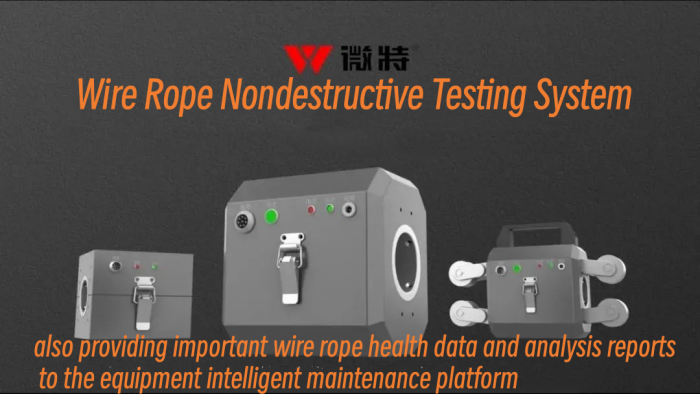

Three types of equipment

For different application scenarios, Weite has launched three types of equipment: online, integrated, and portable, which are suitable for various industries such as ports, ships, roads and bridges, cableways, steel mills, hoisting, construction sites, and petroleum.

1. On-line type: It mainly meets the needs of on-site real-time online detection, alarm, feedback, data analysis and export of test reports, and can be remotely monitored.

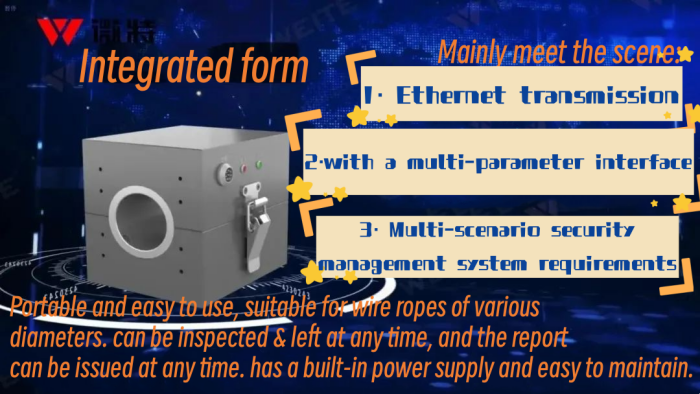

2. Integrated: Ethernet transmission, with multi-parameter interface, which can meet the needs of users for multi-scenario security management systems.

3. Portable: easy to use, suitable for steel wire ropes of various diameters, can be inspected and moved at any time, and reports can be issued at any time, with built-in power supply, and easy maintenance.

The Weite's wire rope non-destructive testing system provides customers with a scientific and effective wire rope maintenance solution. It can not only be used independently, but also provide important wire rope health data and analysis reports to the equipment intelligent maintenance platform, which is an indispensable part of future smart management.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)