A few days ago, the safety monitoring remote management system independently developed and designed by Weite Technologies Co., Ltd. passed the acceptance by the owner in Yongfeng Group Hanzhong Iron and Steel Co., Ltd. and has been put into operation normally.

Shandong Iron and Steel Group Yongfeng Zibo Co., Ltd. was established on August 1, 2016. It is one of the 58 pilot units of mixed reform of provincial state-owned enterprises in Shandong Province. The company's predecessor was Zhangdian Iron and Steel Plant, which was established in 1958. In August 2016, it implemented asset reorganization and introduced strategic investor Yongfeng Group to form Shandong Iron and Steel Group Yongfeng Zibo Co., Ltd.

Shandong Iron and Steel Group

The company has more than 2,200 employees. The main equipment is one 1,350m³ blast furnace, two 120-ton converters, one 1 million-ton high-strength bar production line, two 600,000-ton high-speed wire rod production lines and corresponding desulfurization, power generation and other supporting facilities. It has an annual output. 3 million tons of steel capacity.

The company's main products are high-strength building materials above 500Mpa, and it also has the production capacity of cord steel, welding wire steel, steel strand steel, spring steel, cold heading steel and other types of steel. Won the "Gold Cup Award" of the China Iron and Steel Industry Association, the "Excellent Quality" product honorary title of the China Metallurgical Industry Quality Management Alliance, and passed the "High-strength Steel Bar Product Certification" by the Metallurgical Product Certification Center.

4 video sets of maintenance team

The cooperation project between Weite Technologies Co., Ltd. and Yongfeng Group Hanzhong Iron and Steel Co., Ltd. is a crane safety monitoring remote management system. The system consists of two parts: remote equipment status and video dynamics. It is specially designed for steel mills by Weite Technology Co., Ltd. Crane's customized remote management system for crane safety monitoring.

Weite engineers install equipment on site

The system adopts the system structure of hierarchical monitoring and centralized supervision to realize the on-site safety monitoring of the crane equipment in the production department and realize the alarm and hidden danger control, and then remotely transmit the scattered equipment safety information to the maintenance team, the production department, and the safety and environment department. And other related management departments, complete the synchronization of the security status information of the equipment at all levels, and reduce the management time cost and labor cost through the fast information feedback mechanism. Pointing to clear faults, feedback guarantees quick troubleshooting, ensuring production while greatly reducing time and manpower losses.

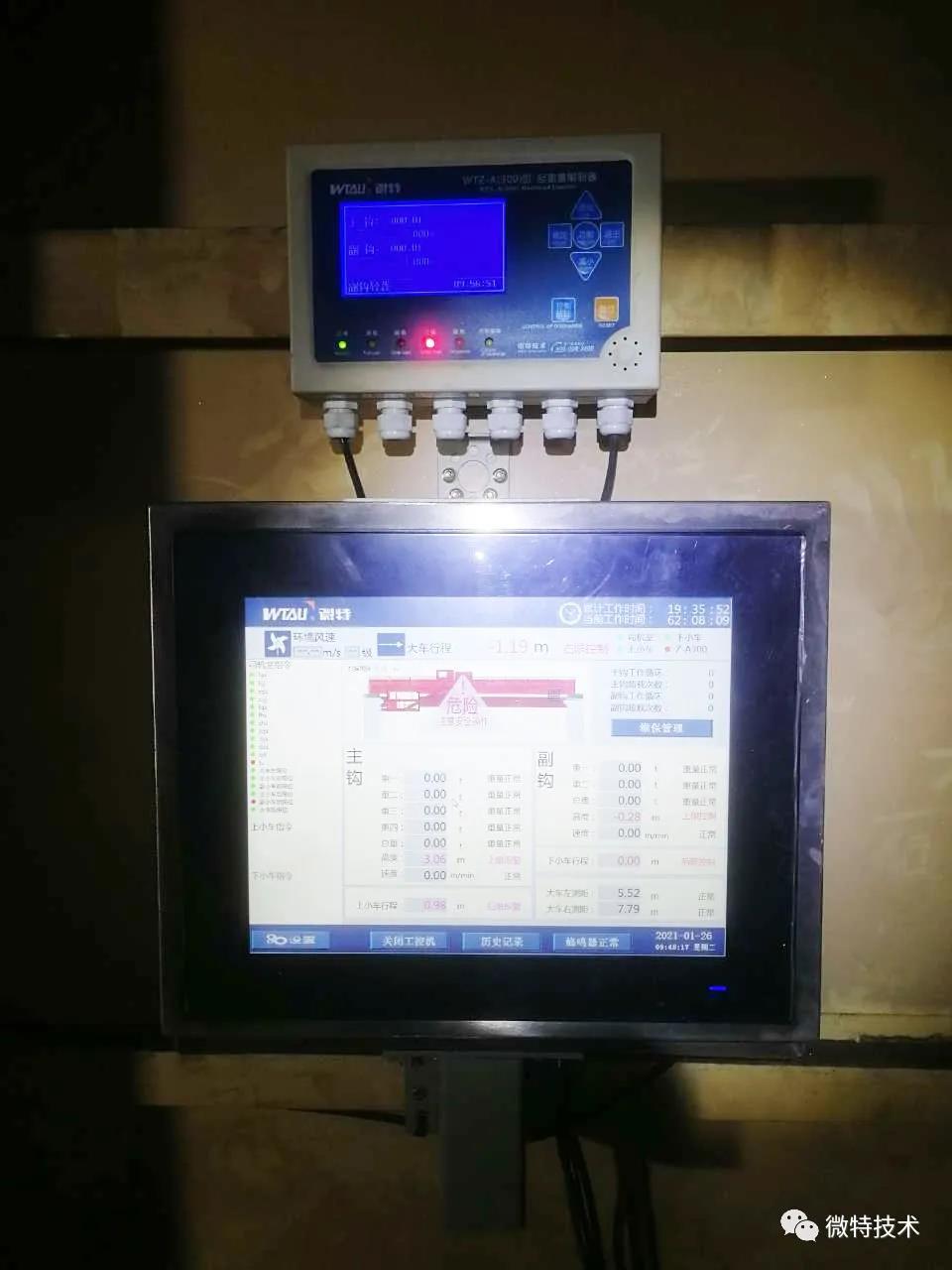

WTAU Brand safety monitoring and management equipment installed on the crane

The WT-SMS-YC security monitoring remote management system customized for Yongfeng Group not only meets the current needs of various users, but also meets the needs of future multi-device cluster management. It is used by steel mills, ports and other enterprises. The necessary process of equipment safety information management and equipment maintenance information management is to respond to the implementation of the "Made in China 2025" strategy for implementing the strategic action plan for a strong manufacturing country.

China implements strategy of manufacturing power

Weite regards quality as its life, and has won long-term cooperation with many large domestic steel companies with reliable quality and reputation, such as Wuhan Iron and Steel, Baotou Iron and Steel, Xiangtan Iron and Steel, Shanxi Iron and Steel, Maanshan Iron and Steel, Xingcheng Special Steel, Sangang, Xinxing Casting Pipe Wait. In the future, Weitetech will keep its original intention as always, and take the mission of making lifting equipment safer and more reliable!

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)