Aug. 12, 2024

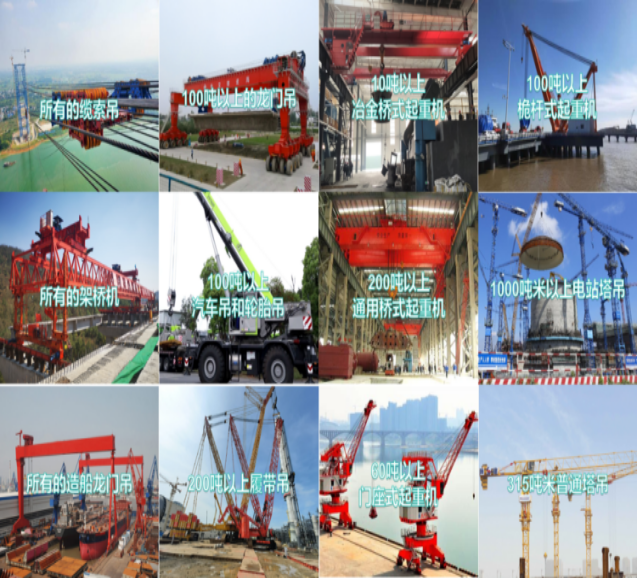

Units with the following types of lifting equipment should not miss it. Is your safety monitoring and management system installed correctly?

According to the requirements of "TSGQ7016-2016", all cable cranes, bridge erecting machines, shipbuilding gantry cranes, gantry cranes over 100 tons, truck cranes and tire cranes over 100 tons, crawler cranes over 200 tons, metallurgical bridge cranes over 10 tons, 200 General bridge cranes above 60 tons, gantry cranes above 60 tons, mast cranes above 100 tons, power station tower cranes above 1000 tons meters, ordinary tower cranes above 315 tons meters.

Why install a monitoring system?

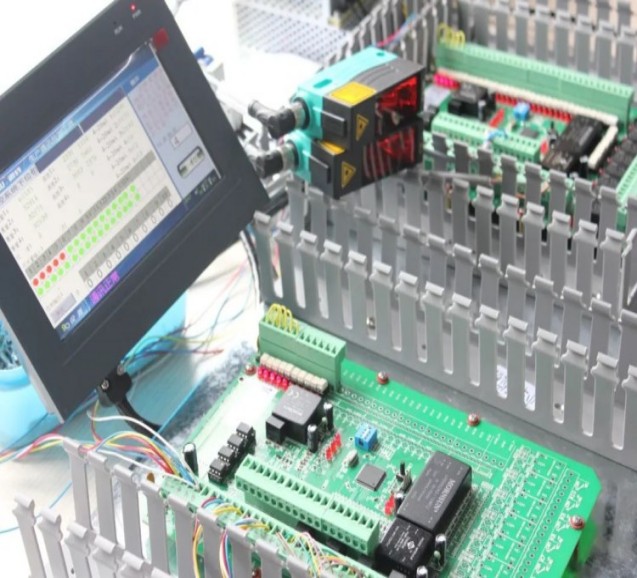

First: All operating data are displayed in real time, allowing operators to understand the current working status;

Second: alarm control for over-limit operation and dangerous working conditions to prevent illegal operations;

Third: record accidents and malfunction phenomena and trace the causes, which is the "black box" function.

So for lifting equipment, the benefits of having a suitable monitoring system are obvious. Why do many users feel that the monitoring system they installed is useless? Asking is just not pretending well enough.

Everyone in the industry uses "GB/T 28264-2017" as the blueprint for configuration. Since each manufacturer has a different understanding of the standard, the initial monitoring system has a variety of weird configurations, so in order to standardize this product Installation and use standards, inspection regulations were born, and the latest standard is "TSG 51-2023". It’s all available online. If you can’t find it, you can send me a private message.

HOT PRODUCTS