Construction Crane Safety Technology Solutions

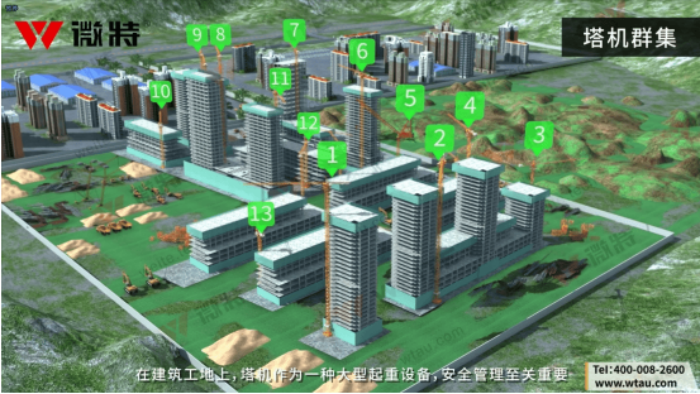

In the field of building ground,tower crane is as a kind of large-scale hoisting equipment,it is very important for its safe management.With the rapid development of the modern sensor technology, the digitization & intelligentization of tower crane becomes a management tendency.

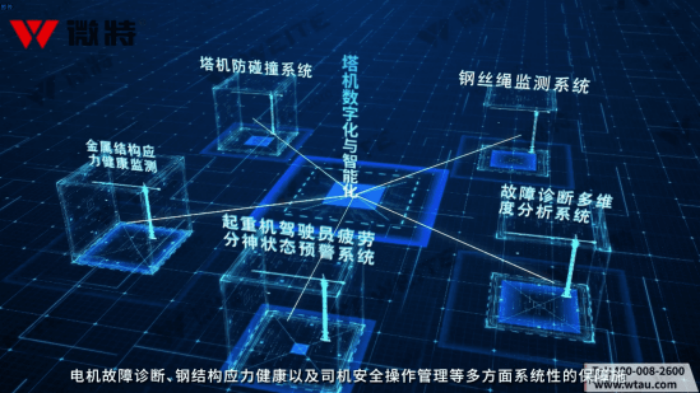

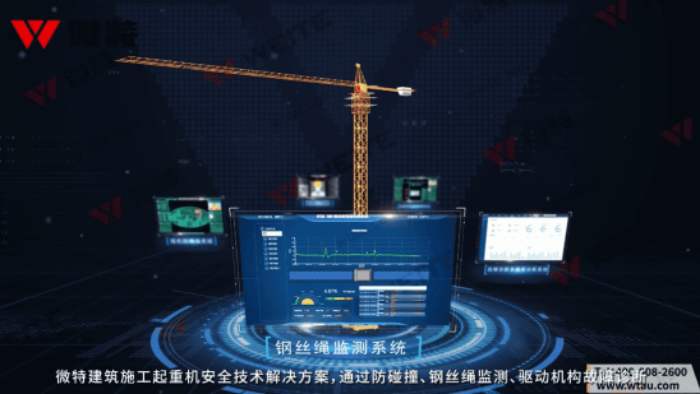

For construction cranes,the Weite special technology construction crane safety technology solution systematically ensures construction safety & intelligent management & maintenance from multiple aspects such as collision prevention, wire rope monitoring, motor fault diagnosis, steel structure stress health, and driver safety operation management, allowing the crane to achieve greater benefits.

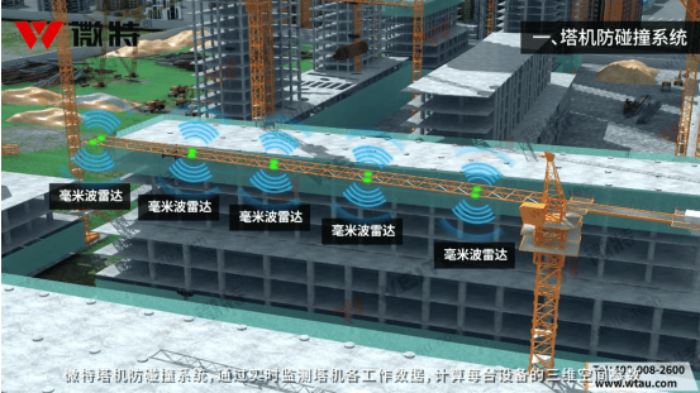

1. collision prevention system of tower crane

Preventing tower crane collisions is a very important safety task at construction sites. The Weite special tower crane collision prevention system monitors each working data of the tower crane in real-time, calculates the three-dimensional spatial parameters of each equipment, and dynamically monitors the surrounding environment. When the tower crane runs too close to other equipment, it sends a danger alarm in advance to prevent collision accidents from happening.

2. wire rope monitoring system

As one of the most important flexible components of cranes, steel wire ropes have defects such as wear, wire breakage, decreased strength, and rust during long-term high-frequency operation. It often leads to serious safety accidents for equipment and personnel. Weite conducts non-destructive testing on steel wire ropes based on electromagnetic testing technology. By automatically collecting changes in the stray magnetic field of steel wire ropes, combined with multiple data algorithms and steel wire rope scrap standards, quantitative detection of defects such as wear, breakage, strand breakage, rust, deformation, etc. of steel wire ropes has been achieved, and maintenance suggestions have been provided.

Non destructive testing is carried out without affecting production, ensuring the safe operation of the steel wire rope.

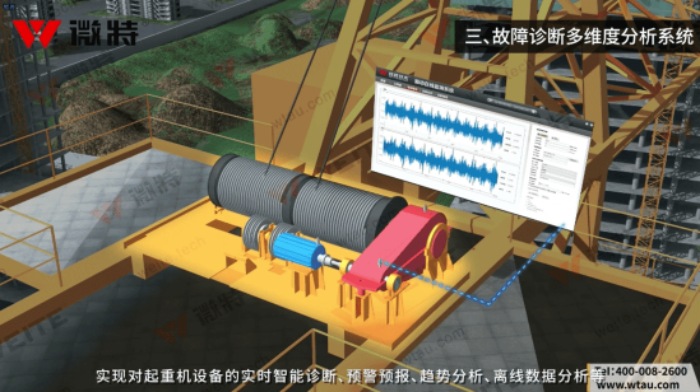

3. multi-dimension analysis system of motor fault diagnosis

The multi-dimensional analysis system for online fault diagnosis of Weite special rotating mechanisms conducts multi-dimensional fusion analysis of vibration, speed, temperature, current and other status signals of crane motors, reducers, wheels, etc. Combined with intelligent diagnostic algorithms, it achieves real-time intelligent diagnosis, pre alarm prediction, trend analysis, offline data analysis, etc. of crane equipment, achieving early diagnosis of fault types, fault probabilities, and fault levels, and providing maintenance suggestions, Ensure the normal operation of the rotating mechanism.

4.Metal structure stress health monitor

The main failure mode of cranes in long-term lifting work is mechanical fatigue damage caused by the influence of alternating stress on metal structures or components under random alternating loads.

Weite analyzes its failure modes and stress conditions, installs stress sensors at key points, monitors stress status and deformation, obtains corresponding stress spectra, and evaluates the safety status of metal structures through mathematical model analysis combined with stress fatigue analysis theory to prevent safety accidents caused by crane metal structure failure.

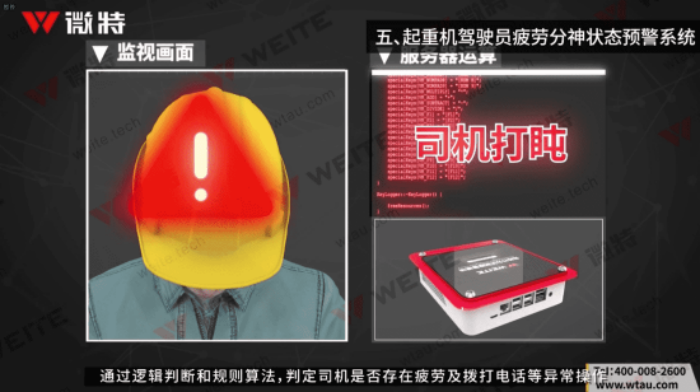

5.Crane driver fatigue distraction state warning system

The system utilizes intelligent cameras to monitor the driver's cab in real-time, and uses graphic algorithms to analyze and process the cab images frame by frame, recognizing the driver's facial status, body posture, mobile phones or items in real-time.

By using logical judgment and rule algorithms, to determine whether the driver is experiencing fatigue and abnormal operations such as making phone calls, and automatically issue an alarm.

The equipment is convenient and practical, with high accuracy, fast feedback speed, and does not affect the normal work of the driver.

The safety technology solution for Weite special construction cranes is achieved through intelligent technical means such as collision prevention, wire rope monitoring, drive mechanism fault diagnosis, steel structure stress health, and driver safety operation management, to maximize construction safety, save costs and increase efficiency, and ensure the personal safety of workers and the smooth progress of the project

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)