Recently, the safety monitoring and management system installed on a certain nuclear power special equipment by Weite Technologies Co., Ltd. and Konecranes has been installed and debugged in a strict and orderly manner by the engineers of both parties. At present, the project has successfully passed the acceptance of nuclear power users. The safety monitoring and management system was put into normal operation.

Konecranes Crane Equipment (Shanghai) Co., Ltd. belongs to Konecranes Group and is a wholly foreign-owned enterprise. Konecranes Crane Equipment (Shanghai) Co., Ltd. was established in 2002 and is a leading crane equipment manufacturer and service provider in the Asia-Pacific region.

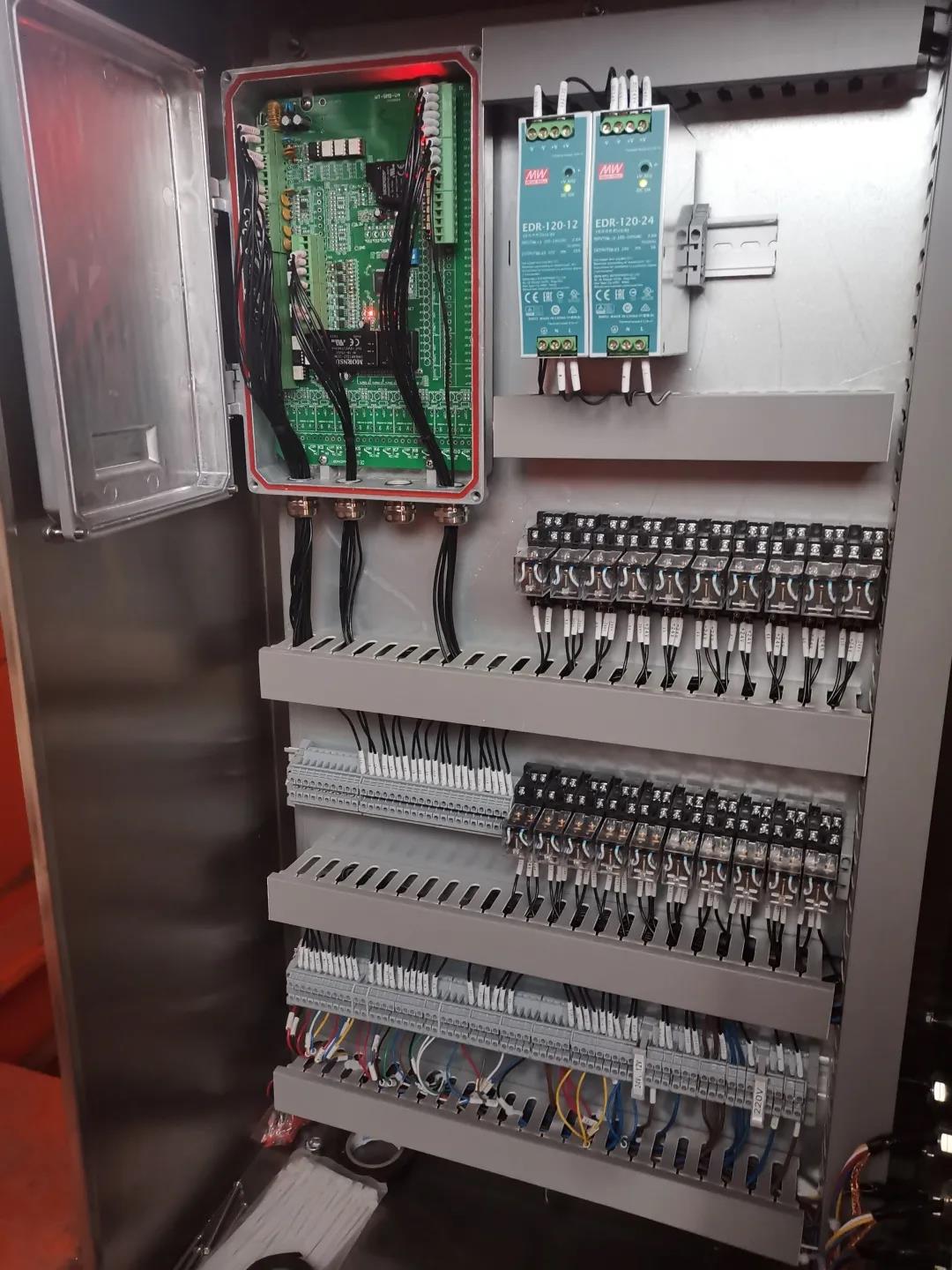

Weite installation of lifting equipment with safety monitoring and management system

Konecranes products mainly include industrial cranes, light lifting equipment, special cranes, nuclear power cranes, heavy forklifts, lifting equipment services, etc. The business involves general manufacturing, electricity, automotive automation, mining, steel, oil and gas, papermaking, Intermodal transportation, rail transportation, ports and other fields.

Main interface of Weite safety monitoring and management system

This project is a customized operating system and software for Konecranes. The system collects various actions and operating parameters of the lower computer in the driver's cab, the lower machine of the trolley, and the monitoring door machine, as well as the weight, the limit of the trolley's stroke, and the status of operating instructions. When each status indicator shows a red light, it means that the corresponding mechanism of the door machine has acted, and a green light means that the corresponding mechanism has not acted. The weight stroke and speed will display the corresponding data on the screen.

This equipment is mainly used for equipment hoisting and transportation of the plant and is located outside the plant. According to the "Notice of the State Council on Further Strengthening the Work Safety of Enterprises" (Guo Fa [2010] No. 23) and the "Regulations for Periodic Inspection of Lifting Machinery", the unit crane needs to be modified and a safety monitoring management system added to improve the crane Safety and reliability, and meet the requirements of regular annual inspection.

Height encoder and mechanical rotation limit

UPS uninterruptible power supply, industrial computer, video monitor, recorder, etc. are installed in the electrical cabinet of the operation room. The relevant data of the cab is communicated with the industrial computer in the driver's cab through 485 communication. The electrical cabinet of the small cab communicates with the industrial computer of the electrical cabinet in the operating room from 485, and communicates with the industrial computer through the communication module conversion, and displays the relevant real-time data on the display.

The mechanical rotary limit switch mechanically controls the upper and lower limits of the hook through the rotary mechanism. The rotary limit switch quantity signal is sent to the lower computer circuit board to display the limit state of the hook through the program. The encoder signal is input to the control box of the lower computer of the trolley. The machine communicates the collected data to the lower computer in the driver's cab, and the lower computer communicates to the industrial computer, the display shows the data, and the lower computer in the driver's cab controls the output.

Laser sensor installation and display

The trolley travel uses a diffuse reflection imported laser sensor. The laser sensor is installed on the top of the trolley traveling mechanism. At the same time, a reflective film is installed at the end of the trolley traveling track to reflect the infrared signal emitted by the laser sensor and display the actual data to the driver’s cab display through communication. . The industrial computer in the driver's cab monitors the travel data of the trolley in real time, and gives an audible and visual alarm when the travel reaches the preset position, and outputs to control the travel of the trolley to avoid danger.

Electric control cabinet for the lower position of the trolley

The lower computer in the trolley engine room collects the brake switch signal, the upper and lower limit signals of the height, the travel data, height data, and weight data of the trolley, and transmits the data to the driver’s industrial computer for real-time monitoring through communication with the driver’s industrial computer. The relevant data is in the instrument On display.

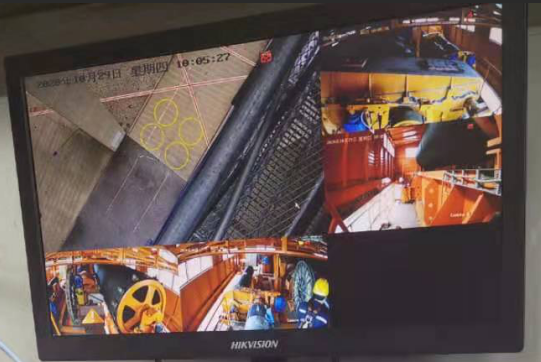

A dome camera in the hoisting area communicates with the video recorder in the driver's cab. The video recorder transmits the video signal to the monitoring display screen to watch whether there is any dangerous operation in the lifting point area in real time. Four cameras are installed in the trolley to check the lifting drum brake and the situation in the trolley.

Camera and display area

This transformation project has received strong support from users. During the special period of the epidemic, the user engineer and the Weite after-sales engineer communicated remotely through video, and completed the installation of all the hardware on the spot. After the epidemic eased, the Weite after-sales engineer went to the site to complete the commissioning, training, and materials collecting and other work.

After installing the safety monitoring management system, it has solved the problem of difficulty in observing the original blind area of the cart and the area of the main hook lifting point. After the transformation is completed, the monitoring system helps the driver to more intuitively understand the operation of the vehicle equipment when operating the equipment, and respond in real time. It provides a data monitoring and video visualization security guarantee for the safety and reliability of hoisting work.

Weite has always focused on research in the field of lifting equipment safety management, adhering to the business philosophy of focusing on user needs, providing users with valuable products and services, leading the development of the lifting safety industry, and being the preferred brand for large and important crane safety monitoring solutions .

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)