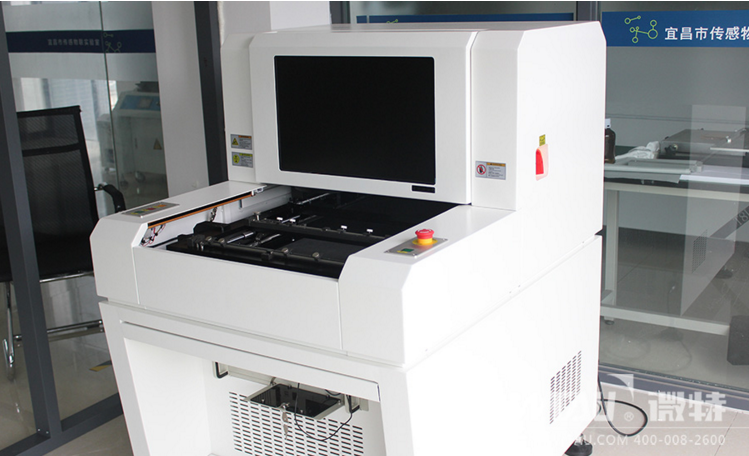

In order to improve the stability of the instrument, the excellent rate of the product, WTAU got automatic optical inspection equipment (Automatic Optical Inspection, referred to as AOI) in the SMT production line. The equipment is mainly used to check the SMT production line on the original placement of the welding quality, installation status and the effect of solder paste printing, with comparing of the "stored" standard parts, AOI can display bad products .

AOI equipment used three primary colors (red, green, blue) principle to make up different colors through the optical principle, with optical principles of specular reflection, diffuse reflection, slope reflection, rapid identification of PCB chip components Welding quality, through the analysis can be targeted to improve the production process, improve product quality, to avoid bad products into the next production process.

In the whole production process, due to the impact of various subjective and objective factors, it will inevitably lead to changes in quality, and even produce waste. Therefore, in order to ensure the quality, we use this equipment as a control after welding a control process, that can pick out waste, bad products.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)